Recap of Supply Chain Management Webinar

Investing in the Supply Chain is Critical to Achieving Family Planning Goals

On November 19, the High Impact Practices for Family Planning (HIPs) Partnership, in collaboration with Family Planning 2020 (FP2020) and IBP Network, hosted a webinar where family planning supply chain experts presented the most important intervention areas and tips from experience. Missed this webinar? Read on for a recap, and follow the links below to watch the recording.

Commodity stockouts of popular contraception products are common in low- and middle-income countries (LMICs). This webinar covers the main points of the newly updated brief “Supply Chain Management: Investing in the supply chain is critical to achieving family planning goals,” which follows the idea that a well-functioning family planning supply chain is essential to ensure access to a variety of methods, support voluntary choice, and achieve contraceptive goals.

Introduction to Family Planning Supply Chain Management

Moderator Martyn Smith, Managing Director, FP2020

The percentage of facilities stocked out, by method offered, is FP2020’s Core Indicator 10, which has greatly evolved over time. Today, we have much more robust data that can show how the various bottlenecks in the supply chain system contribute to stockouts of modern contraceptives, thus limiting achievement of family planning goals. These goals have never been more important than now, during the COVID-19 pandemic.

Interventions & Tips to Strengthen Family Planning Supply Chain Management

The brief outlines the four main intervention areas in family planning supply chain management and tips for their implementation, as follows:

- Increase data visibility and use: conduct systematic assessments to identify bottlenecks and solutions

- Accelerate product flow: map duplication or wastage

- Professionalize the workforce: foster strong leadership for supply chain

- Capitalize on private sector capacity: conduct private sector capability analysis and consider supportive policies

These investments have proven to be paramount to mitigating the effects of COVID-19, and will be integral in handling other future shocks to the system.

You Can’t Manage What You Can’t See

Julia White, Director, Global Family Planning Visibility and Analytics Network (GFPVAN), Reproductive Health Supplies Coalition (RHSC)

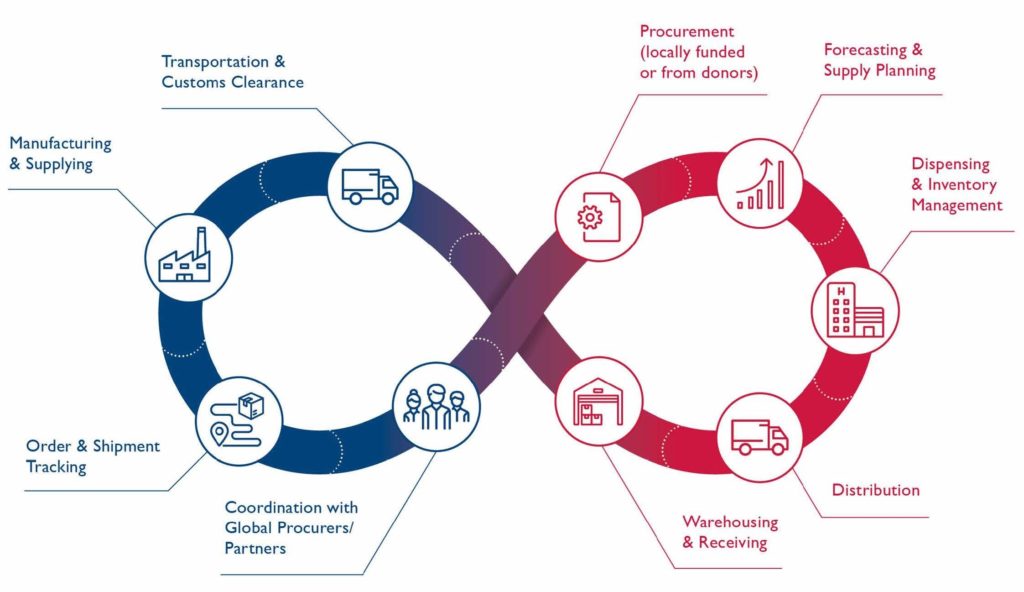

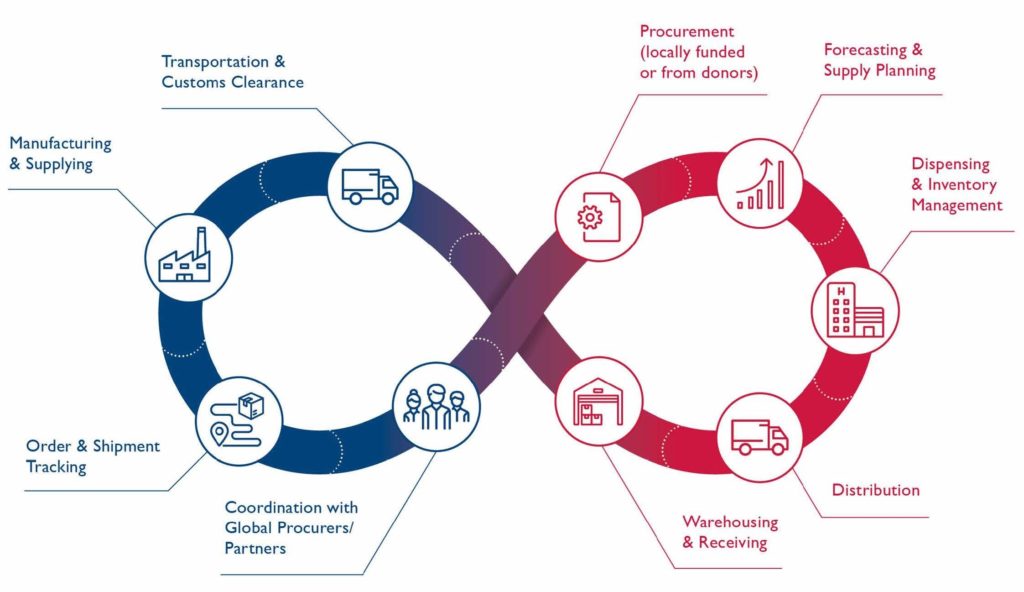

The global supply chain system is a complex ecosystem of trading partners spread across the globe (donors or procurers, shippers, manufacturers, and central medical stores). Within this web are different decision-makers, constantly thinking about how many products to produce and for whom, when to ship them out, and how long will they take to arrive. Any insufficient or mislabeling of data creates disruptions in the supply chain and causes stockouts.

Reproductive Health Supplies Coalition: It’s About Supplies

RHSC is the world’s largest network of reproductive health supply organizations, including 470 public entities, private corporations, and nongovernmental organizations (NGOs) working in LMICs. Over time, RHSC has developed various mechanisms and groups to aid in their work along each point of the supply chain.

It proved to be very difficult to coordinate these efforts due to poor technology, growing complexity in the ecosystem, and siloed and duplicative processes. To tackle this, the coalition looked at 1) the people and the processes involved, and 2) what technology can support them?

The Global FP VAN (GFPVAN) grew from the vision that all family planning supply chain players are connected on a robust virtual platform where they share data and collaborate on decision-making.

The GFPVAN: Countries at the Heart of the Ecosystem

The GFPVAN and its partner countries rely on the link between global manufacturers, shippers, and the in-country players who bring products to facilities. The goal is to improve technology, aggregate, share, and align country demand data with production, procurement, and funding.

“[The VAN] is not just a technology fix. The technology is there to empower the people and the processes, who are the ones moving the product through the supply chain. It’s important to figure out who are these people and processes, and then figure out the policies and technology that can support them.”

Since the VAN went live last year, countries have integrated the platform into their health systems strengthening efforts, using it as their “one-stop visual” that tracks planned and incoming shipments against consumption patterns and inventory.

Country Impacts

Malawi fully utilized an order’s shipment tracking data, following it from the manufacturer to its arrival in the country. This was critical with the onset of Cyclone Idai: the VAN flagged over-forecasting for implants, so managers were able to readjust as needed (expedite, delay, or cancel shipments).

Through the VAN, Nigeria succeeded in streamlining communication across the supply chain, working across different levels from donors to commodity tracking task forces in-country.

Speeding Up Product Flow through the Supply Chain

Prashant Yadav, Senior Fellow, Center for Global Development

Imagine yourself as a family planning commodity sitting in a box of health products. Think about the experience, everything that happens to you from the time you leave the factory until the time you reach a client. The harsh reality is that, due to the speed of supply chain flow in LMICs, the majority of this experience is just sitting in a box in a storage room.

To explain this, Prashant uses what he calls “flow velocity.” When we talk about speeding up the flow, it’s not just about moving from stage to stage more often–it’s also about developing shorter and more frequent planning cycles.

The “Forecasting Trumpet”

A key element of flow velocity is forecasting. It is easier and more accurate for a clinic to predict how many refills of a product they will need from one day to the next, but not so easy for them to think about it across months. However, this is the “side of the curve” to be thinking on. Increasing flow velocity will improve forecast accuracy.

Creating Fewer Layers

Country analysis has shown that if there are too many layers in the supply chain, information and accountability become more diffused. This results in stockouts, with no one being able to identify what went wrong and where in the chain.

Prashant refers to this as the “Bullwhip effect”: for every additional layer in the supply chain where you hold inventory, any small variation in customer demand starts getting amplified as you go upstream. Thus, changes in client demand make it very difficult to plan.

“Speeding up product flow through the supply chain helps national, regional, and global supply end demand signal remain in closer sync with end demand.”

Overview of Ghana’s investment in Family Planning Supply Chain Management

Claudette Diogo, Family Planning Programme, Ghana Health Service (GHS)

Ghana has heavily invested in its supply chain management. The four pillars of Ghana’s master plan for family planning supply chain management are coordination, innovation, transparency, and sustainability. This all ties into the overall family planning goal of making safe contractive methods affordable, available, and accessible. A yearly quantification exercise brings together the main family planning stakeholders in the country (development and government partners and family planning NGOs) to review and develop a data-driven supply plan to guide the funding effort.

The Inter-agency Coordination Committee on Contraceptive Security (ICC/CS): “No Commodity, No Program”

The ICC/CS includes donor partners, social marketing organizations, pharmaceutical manufacturers, and implementing partners in family planning and reproductive health. The committee meets regularly to analyze status reports and make key decisions to enhance commodity availability. The committee increased investment in warehouses and distributions, with a systematic placement of central- and regional-level medical stores, and scheduled delivery times via delivery shuttle.

Data Visibility and Reporting: The GFPVAN in Ghana, and More

As Julia presented, Ghana has been using the VAN platform to track inventory reports and supply plans, which enables the GHS to pinpoint when and how to intervene. Other implemented systems include:

- A Logistic Management Information System, which provides real-time data.

- The District Health Information Management System provides national-level data consolidated from service providers over a certain period.

- Monthly status reports show stock availability to help plan for redistributions.

Capacity Building of Supply Chain Practitioners

In terms of the third implementation area for family planning supply chain management mentioned at the beginning of the webinar, the GHS also focuses on training practitioners to proficiently improve supply chain management. To this end, Regional Resource Trainers train providers on family planning methods and logistics management, as well as commodity management for managers of health facilities to improve stock management at the facility level.

Overview of Ghana’s investment in Family Planning Supply Chain Management

I’m interested in hearing about private sector capacity building in Ghana with the Zipline [a distribution method using drones]. Do you have any views?

Claudette: We actually work in relation to the private sector through social marketing organizations, so when we develop strategies and training materials together, these private entities can use their funding to support their needs. We invite them to trainings to ensure that the private sector capacity is improving too.

Is there a risk of hiding and marginalizing local manufacturers such as those up-and-coming companies in Africa, struggling to gain a hold in the SRH commodity industry?

Julia: Collaboration and visibility are at the heart of the VAN. This means the more manufacturers, the better. We want to understand the manufacturers these smaller companies are working with and what opportunities there are to work together. The point of the VAN is that we can work with multiple entities, so if these companies are interested and willing to share their data, we have no issue including them in the platform.

What, in your opinion, is the key supply chain indicator, thinking about the box analogy and demand signals?

Prashant: First, I don’t think we should be looking for just one indicator, we should be thinking about two or three ideally. I do think we should be thinking about service level in a multi-dimensional way. Stockouts are a common indicator used for this in surveys, but I think we should expand that measure, and think about service level through routine data, and we should systemize this. Second, some of the indicators are part of a hierarchy of indicators. Some are at the top level, and then the following level, etc.